Diesel generators require less maintenance due to their durability, reliability, and sturdiness, and also they are considered cheaper to operate due to the low fuels costs as compared to the other types of fuels such as gasoline and propane.

…they can take on heavy loads for long hours and start off the power supply on full load within minutes. They must be regularly maintained to ensure they provide the same quality power throughout their service lives.

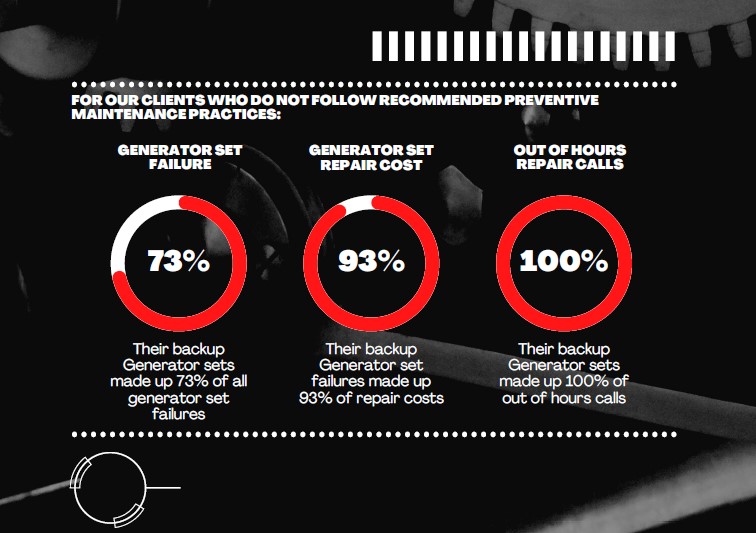

We looked at the data and run the analysis for our two types of clients; those who follow the manufacturer’s maintenance recommendations and those who look to save money by refusing to carry out the recommended preventive maintenance services.

We found that trying to save money by ignoring the recommended services will cost you 52% more.

Preventive Maintenace cost

Our Clients who spent monies to follow the recommended service procedures, spend 52% less money on their power generators.

GENERATOR SET FAILURES: When we analyzed the instances where the power generators failed to startup or deliver the needed power to our clients, we noticed that 73% of the time, these power generators belonged to the group of clients who do not carry our proper maintenance services.

GENERATOR SET REPAIR COST: The clients who prefer to skip maintenance pay for 93% of all our repair bills. Generator set downtimes cause inconveniences, but most clients overlook the lost revenues and man-hours wasted when there is no power. When these costs pile up, they have a strong and negative impact on your bottom line.

OUT OF HOURS REPAIR CALLS: 100% of our overtime callouts came from clients who do not follow the right maintenance practices. Overtime is expensive to you as a client, but it is more expensive to the maintenance crew as they take these overtime periods out of the time they would normally spend with their family and loved ones.

Nope! On the surface, it looks like you’re saving money by skipping your oil change, but that’s not the case. Doing so will cost you more money and reduce the overall lifespan of your expensive assets.

Our Preventive Maintenance Tips

Routine General Inspection

During the running of the diesel generator, the exhaust system, fuel system, DC electrical system, and engine require close monitoring for any leaks that can cause hazardous occurrences. As with any internal combustion engine, proper maintenance is essential. Diesel engines are no exception, and the most important maintenance is oil changes at every 250 hours of operation for a long and trouble-free life assurance.

Lubrication Service

The engine oil must be checked while shutting down the generator at regular intervals using a dipstick. Allow the oil in the upper portions of the engine to drain back into the crankcase and follow the engine manufacturer’s recommendations for API oil classification and oil viscosity. Keep the oil level as near as possible to the full mark on the dipstick by adding the same quality and brand of oil.

The oil and filter must also be changed at acclaimed time intervals. Check with the engine manufacturer for procedures for draining the oil and replacing the oil filter and their disposal is to be done appropriately to avoid environmental damage or liability.

Cooling System

Check the coolant level during shutdown periods at the specified interval. Remove the radiator cap after allowing the engine to cool, and, if necessary, add coolant until the level is about 3/4 in. Heavy-duty diesel engines require a balanced coolant mixture of water, antifreeze, and coolant additives. Inspect the exterior of the radiator for obstructions, and remove all dirt or foreign material with a soft brush or cloth with caution to avoid damaging the fins. If available, use low-pressure compressed air or a stream of water in the opposite direction of normal air flow to clean the radiator.

Fuel System

Diesel is subject to contamination and corrosion within a period of one year, and therefore regular generator set exercise is highly recommended to use up stored fuel before it degrades. The fuel filters should be drained at the designated intervals due to the water vapor that accumulates and condenses in the fuel tank. Regular testing and fuel polishing may be required if the fuel is not used and replaced in three to six months. Preventive maintenance should include a regular general inspection that includes checking the coolant level, oil level, fuel system, and starting system. The charge-air cooler piping and hoses should be inspected regularly for leaks, holes, cracks,dirt and debris that may be blocking the fins or loose connections.

Testing Batteries

Weak or undercharged starting batteries are a common cause of standby power system failures. The battery must be kept fully charged and well-maintained to avoid dwindling by regular testing and inspection to know the current status of the battery and avoid any start-up hitches of the generator.

Routine Engine Exercise

Regular exercising keeps the engine parts lubricated and thwart oxidation of electrical contacts, uses up fuel before it deteriorate, and helps to provide reliable engine starting. Engine exercise is recommended to be executed at least once a month for a minimum of 30 min. loaded to no less than one-third of the nameplate rating.

Keep your Generator Clean

Oil drips and other issues are easy to spot and take care of when the engine is nice and clean. Visual inspection can guarantee that hoses and belts are in good condition. Frequent checks can keep rodents, wasps and other nuisances from nesting in your equipment.

Categories: blog

Tags: #mining, #filtration, #Powergent, #Engines

Source: Internal

Author: VALERIAN M. NOFONG JR.

Date: MARCH 17, 2022